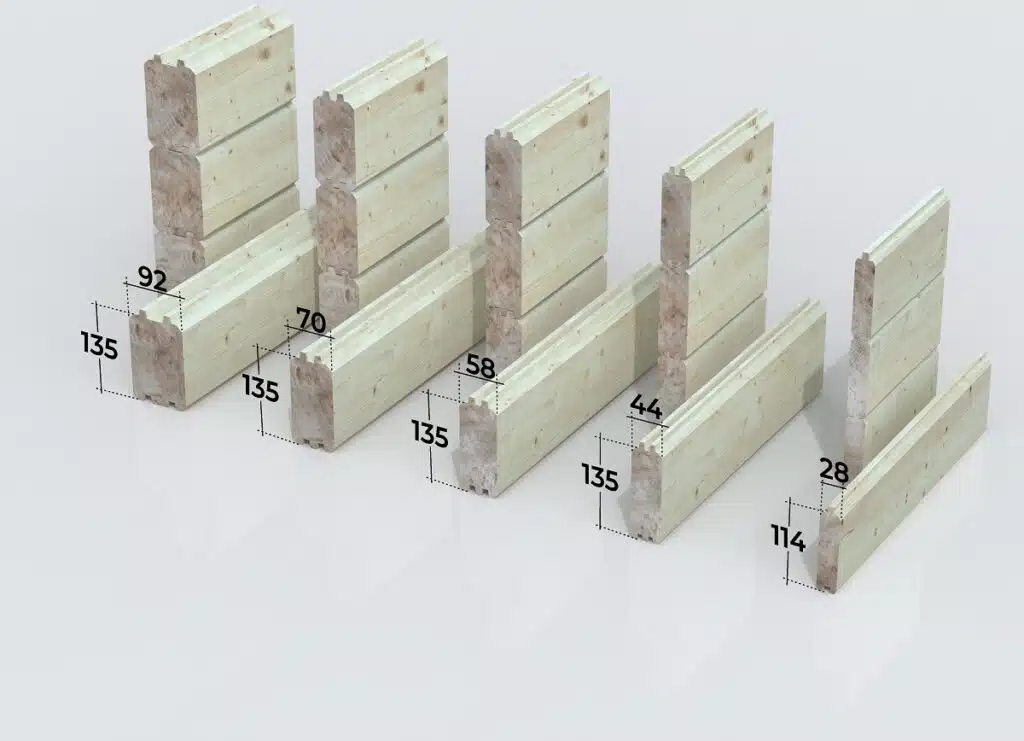

Wall Thickness Upgrade

Our cabin models are designed with strength and durability in mind and so are produced in the wood thickness that delivers these properties with lower costs. However, upgrading to thicker timbers will only add to the cabins strength and longevity as well as creating a more solid feeling building, with some improvement on thermal properties.

Want to discuss over phone. Let us call back to you

If you need any additional info regarding any product, please fill in the below form and we will get back to you, usually the same or next working day.

Have any questions regarding some product?

If you need any additional info regarding any product, please send us your questions.